Graco Expands QUANTM™ Pump Line to Advance Industrial Efficiency and Automation

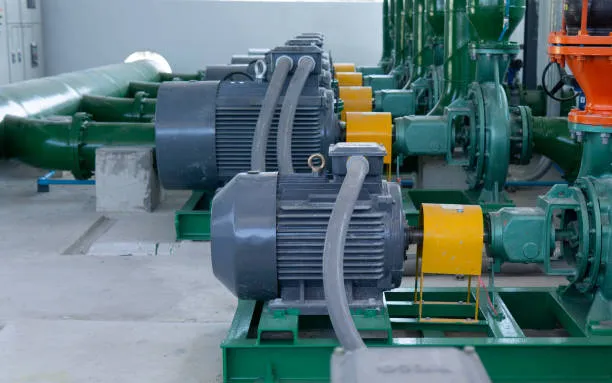

Graco Inc., a global leader in fluid handling solutions, has announced the expansion of its widely acclaimed QUANTM™ electric double diaphragm (EODD) pump line. This latest evolution of the QUANTM series reaffirms the company’s enduring commitment to meeting the needs of industrial manufacturers through forward-thinking innovation and reliable performance. With the new enhancements, Graco delivers increased energy efficiency, streamlined maintenance, and greater compatibility with factory automation systems—making the pumps a smart investment for modern production environments.

For nearly a century, Graco has built a reputation for engineering excellence in fluid management. The QUANTM line exemplifies this legacy, combining advanced technology with a practical design philosophy to support manufacturers in achieving measurable operational improvements. With the addition of the 480V power range and other design refinements, the QUANTM line continues to lead the industry in both performance and sustainability.

Innovation That Delivers Measurable Value

At the heart of the enhanced QUANTM pumps is Graco’s proprietary XTREME TORQUE™ motor, a compact and highly efficient drive system that significantly reduces the overall size and weight of the pump. This innovative motor not only improves ease of deployment but also cuts down on space requirements in crowded production facilities. These compact pumps are particularly attractive to facilities seeking space-saving solutions without sacrificing power or performance.

The addition of a 480V power option opens the door to even more operational flexibility, allowing for cost-effective drop-in replacements across a broader range of existing systems. This makes QUANTM pumps not only a future-ready solution but also a practical upgrade for legacy infrastructure.

“Our customers aren’t interested in hype or vague sustainability claims,” said Paul Treml, Vice President of Marketing at Graco. “They want proof. And QUANTM delivers. Companies that have integrated these pumps into their systems are already seeing quantifiable gains in reliability, energy efficiency, and workplace safety.”

Addressing the Four Pillars of Industrial Performance

Graco’s upgraded QUANTM pumps are built around four core pillars that define modern industrial success: energy efficiency, reliability, safety, and automation readiness. These pillars reflect the practical needs of today’s manufacturers, particularly those focused on improving productivity while reducing operational costs and environmental impact.

1. Energy and Cost Savings

One of the most compelling features of the QUANTM line is its remarkable energy efficiency. The pumps are engineered to be up to 80% more energy-efficient than traditional air-operated double diaphragm (AODD) pumps, a benefit that translates directly into lower electricity bills and faster returns on investment.

For many users, this means the pump pays for itself in less than a year—an impressive timeline by any standard. Additionally, these energy savings may qualify users for government incentives, rebates, or sustainability credits, depending on their region and industry.

2. Simplified Maintenance and Longevity

Maintenance is often a major cost driver in industrial operations, particularly when equipment involves complex parts or is prone to failure from clogged lines or sensor malfunctions. QUANTM pumps are designed to reduce those burdens with a simplified construction that eliminates the need for pressure sensors and other components that typically require routine inspection or replacement.

The pump’s robust internal architecture also supports the handling of challenging fluids, including shear-sensitive liquids, abrasive slurries, aggressive chemicals, and solids-laden mixtures. This versatility makes QUANTM pumps ideal for a wide array of applications, from paint and coatings to food processing and pharmaceuticals.

3. Enhanced Workplace Safety and Comfort

Noise pollution is a growing concern in industrial settings, especially in facilities operating under strict health and safety guidelines. QUANTM pumps reduce operating noise by as much as 90%, creating a quieter and more comfortable environment for plant personnel.

This dramatic noise reduction not only improves workplace conditions but also supports compliance with occupational safety regulations. For plant managers, this means fewer complaints, improved worker satisfaction, and potentially lower costs associated with hearing protection and safety equipment.

4. Built for Automation

Modern factories increasingly rely on smart automation to streamline production, minimize error, and maintain consistent quality. The QUANTM line is designed from the ground up to integrate seamlessly with automated systems.

Its plug-and-play compatibility with standard power outlets (110V, 240V, and now 380V/480V) simplifies installation, while its intelligent control systems allow for real-time monitoring and optimization within Industry 4.0 frameworks. This connectivity ensures that the pump not only performs reliably but also contributes valuable operational data to broader system analytics.

A Versatile Solution for Diverse Industries

According to Matthew Bergman, Graco’s Global Product Manager, the QUANTM pump line is seeing widespread adoption across verticals ranging from general manufacturing and chemical processing to food, beverage, and hygienic applications. Its adaptability and cost-effectiveness make it particularly attractive to companies seeking to upgrade their systems without overhauling existing infrastructure.

“It’s an incredibly versatile pump,” Bergman explained. “It’s built to handle a wide spectrum of fluids and applications, and its energy savings alone can fund its purchase within months. That’s a compelling story for any company looking to modernize its operations. We’re seeing adoption not just in North America but across Europe, Asia, and South America as well.”

Driving Global Sustainability Through Practical Innovation

While many companies today are quick to promote their sustainability goals, Graco is demonstrating measurable progress through engineering. The QUANTM pump line doesn’t just promise greener operations—it delivers real reductions in energy consumption, waste, and downtime. This practical approach to sustainability aligns with global efforts to decarbonize industry while maintaining high levels of productivity and profitability.

The company’s commitment to environmental stewardship is embedded in its product development, manufacturing processes, and global service network. Graco’s engineers continue to work closely with end-users to fine-tune pump performance for specific applications, ensuring optimal results with minimal environmental impact.

A Legacy of Excellence

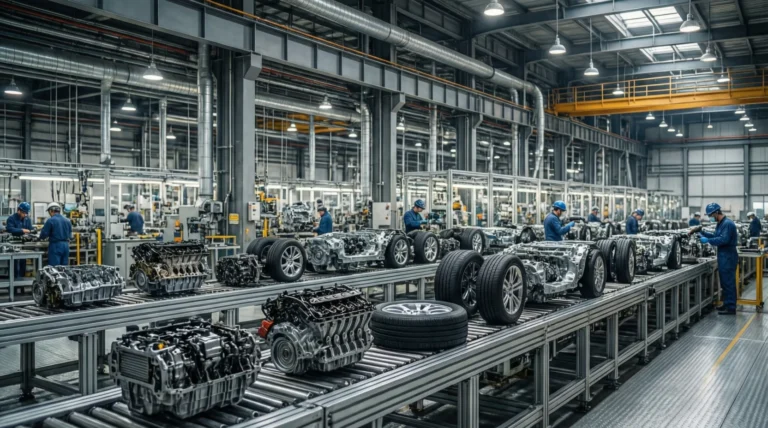

Headquartered in Minneapolis, Graco Inc. has built a legacy of excellence in fluid handling technologies. The company designs, manufactures, and markets a wide range of equipment for moving, measuring, controlling, dispensing, and spraying fluid and powder materials. Graco’s products serve critical roles in industries ranging from automotive and aerospace to construction and maintenance.

With its nearly 100-year history and a global presence, Graco is trusted by professionals around the world to provide durable, efficient, and innovative solutions. The expansion of the QUANTM pump line is just the latest example of how Graco continues to lead by example—pushing boundaries, embracing sustainability, and delivering tangible value to its customers.