Plugged In: A Lasagna-Lover’s Look Inside EV Battery Cell Anatomy”

They say “food is fuel,” EV Battery Cells and in the case of electric vehicles (EVs), that metaphor is more than just clever — it’s an unexpectedly helpful way to understand one of the most complex components of an EV: the battery. Specifically, the battery cell. Surprisingly, the inner structure of an EV battery cell shares more than a passing resemblance to your favorite Italian comfort food — lasagna. Layered, carefully constructed, and absolutely vital to the experience.

Creating a great lasagna requires deliberate layering, the right ingredients, and a properly heated oven. Similarly, building a high-performance EV battery involves intricate engineering ,EV Battery Cells careful selection of materials, and extremely precise assembly. But when you break it down, both share a simple truth: it’s all about the layers. So if you’ve ever made or eaten a good slice of lasagna, you’re already halfway to understanding how an EV battery cell works.

Let’s peel back the foil and dig in.

The Bigger Picture: Battery Packs, Modules, and Cells

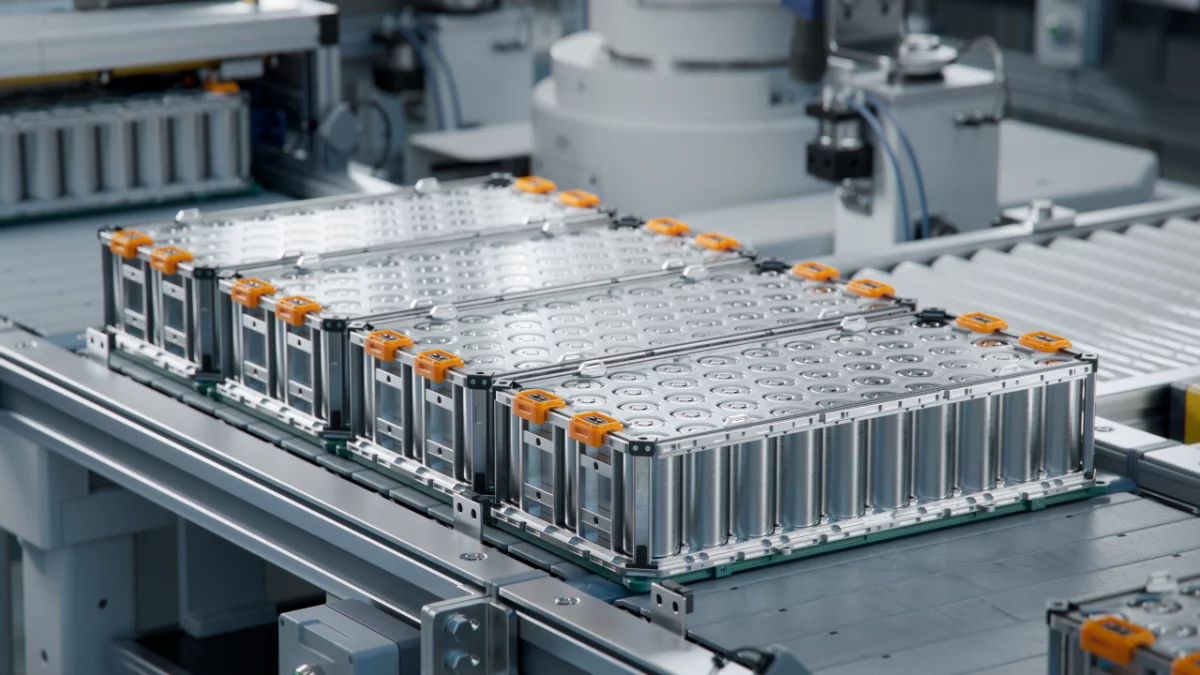

When people think of EV batteries, they often imagine a large, solid slab positioned beneath the floor of the car. That’s the battery pack —EV Battery Cells the complete system that powers the vehicle. But what’s inside that pack? In reality, it’s a modular structure composed of multiple battery modules, each of which contains battery cells — the true source of energy.

To stay with our lasagna analogy: imagine the battery pack as a giant industrial oven loaded with pans of lasagna. Each “pan” represents a module, and within each pan are multiple portions — those are the battery cells. For instance, many modern EVs — such as those produced by General Motors — use battery packs with around 10 modules, and each module houses about 24 pouch-format battery cells. That’s 240 “slices” of electrical lasagna working together.

Though the outer appearance might suggest a monolithic power source, the energy is actually delivered through the coordinated interaction of EV Battery Cells hundreds of individual cells. And it’s inside these individual battery cells where the real electrochemical magic — and innovation — happens.

A Close-Up Slice: What’s Inside a Battery Cell?

So what’s really inside a single pouch-format battery cell?

Picture a single-serving container of lasagna. That plastic or foil-wrapped exterior is like the cell casing — it holds everything inside, keeps it sealed from moisture and air, and provides a basic structural layer. Once you “open” the cell casing, you’ll find a tightly packed stack of electrode layers, EV Battery Cells much like a neatly sliced lasagna reveals pasta, sauce, and cheese stacked in a repeating pattern.

Each battery cell contains two essential electrodes: a positively charged cathode and a negatively charged anode. These aren’t just metal plates — they’re actually very thin sheets of foil (called current collectors) coated with different chemical materials that store and release energy.

- The cathode uses an aluminum foil EV Battery Cells collector and is coated with active materials (often a lithium metal oxide) that attract lithium ions. Think of the cathode as the savory tomato sauce in your lasagna — rich, complex, and the primary flavor layer.

- The anode uses a copper foil coated with materials like graphite, which release lithium ions during discharge. It plays the role of the creamy ricotta — essential for balance, and a key player in delivering the “texture” or performance of the battery.

Now, in a good lasagna, you can’t have sauce and cheese smearing into each other unchecked — you need structure. In food, pasta sheets perform that job, keeping each layer distinct and organized. In a battery, that job is handled by the separator — an ultra-thin polymer film that keeps the cathode and anode from touching and short-circuiting, while still allowing lithium ions to pass through.

Together, the cathode, separator, and anode are stacked in repeating layers — often around 20 or more layers per cell — forming a tidy “electrochemical lasagna” that stores and releases energy.

The Flow of Power: How a Battery Cell Works

Understanding the anatomy is one thing. But how does it all function? To deliver power to an EV, both ions and electrons need to move — but they take different routes.

- Lithium ions, which are the key chemical carriers of energy, travel within the battery cell. When the battery is discharging, the ions move from the anode (ricotta) through the separator (pasta) and into the cathode (sauce). When charging, they go in reverse. These ions don’t just float aimlessly; they travel through a specialized substance called the electrolyte, a gel-like solution that helps them move across the layers. You can think of the electrolyte like the moisture in cooked pasta — without it, the dish is dry and rigid, and nothing blends properly.

- Electrons, on the other hand, travel outside the cell. When energy is released, electrons flow out of the anode, through the car’s electrical system (powering everything from the motor to the stereo), and re-enter the cell at the cathode. These electrons don’t pass through the separator but instead travel via an external circuit — like a fork picking up a bite and delivering it to your mouth, before returning for another bite.

This back-and-forth movement of ions inside the cell and electrons through the circuit is what powers an EV. And it happens thousands of times per second across hundreds of cells.

The Essential Ingredients of Every Cell

At the end of the day, regardless of chemistry tweaks or manufacturing variations, most EV battery cells are built using the same core ingredients — like the timeless building blocks of lasagna:

- Cell casing – protects and contains the internals

- Cathode sheets – aluminum foil + active material

- Anode sheets – copper foil + active material

- Separator sheets – keeps electrodes apart

- Cathode terminal – exit point for electrons

- Anode terminal – entry point for electrons

- Electrolyte – enables ion movement inside the cell

These components work in harmony to charge and discharge power effectively, safely, and repeatedly.

The Innovation Layer: Tinkering with the Recipe

Just like a chef might experiment with new ingredients or layering techniques to perfect a lasagna, battery engineers are constantly pushing boundaries. Each time you hear about a breakthrough in EV battery technology — like increased range, faster charging, or lower cost — it’s likely that one or more of these seven ingredients have been modified or optimized.

Some current trends include:

- Solid-state electrolytes replacing liquid or gel versions for better safety and energy density

- Silicon-based anodes offering higher storage capacity than traditional graphite

- Cobalt-free cathodes improving sustainability and cost

- New separators designed for enhanced thermal stability

And since an EV uses hundreds of cells, even small improvements in one layer can have outsized impacts on overall vehicle performance. A new separator design or a tweak in electrode coating can translate into longer driving range, faster charging times, or improved durability over the vehicle’s lifetime.

Final Bite: What We’ve Learned

So, whether you’re an engineer or a foodie, understanding EV battery cells through the lens of lasagna makes the subject more digestible. From layered construction to ingredient precision, from internal ionic flow to external electron journeys, a battery cell is both simple and elegant in concept — even if it’s complex in practice.

As electric vehicles continue to evolve and become more mainstream, the tech behind them is only getting more sophisticated. But the core idea — stacking layers of specially treated materials to store and release energy — remains the same.

And just like perfecting a lasagna recipe, getting EV batteries right is an evolving craft, combining tradition, science, and a bit of creativity.

Bon appétit — and stay tuned for more tasty takes on electrification.