EV Plant Construction Market Poised for Strong Growth Through 2030 as Automakers Accelerate the Shift to Electric Mobility

The “EV Plant Construction – Global Strategic Business Report” from ResearchAndMarkets.com provides a detailed examination of one of the most critical enablers of the electric mobility transition: the rapid expansion of dedicated electric vehicle (EV) manufacturing facilities worldwide. Valued at US$40.1 billion in 2024, the EV plant construction market is forecast to climb to US$64.4 billion by 2030, growing at a compound annual growth rate (CAGR) of 8.2% during the period 2024–2030.

This growth reflects the unprecedented surge in EV demand, as well as the strategic investments by automakers, governments, and allied industries to secure future production capacity, stabilize supply chains, and align with global sustainability goals.

Why EV Plant Construction Is Accelerating

The rising adoption of electric vehicles is the most powerful driver behind the construction of new plants. With global consumers increasingly shifting away from internal combustion engine (ICE) cars, and governments setting aggressive timelines for phasing out ICE models, automakers are left with no choice but to expand electric manufacturing infrastructure.

These facilities are not only designed to build EVs at scale but also to manufacture their most complex components—batteries, motors, and electric drivetrains. Some are newly built “greenfield” plants, while others are retrofitted existing factories adapted for EV assembly. In both cases, the scale of investment is significant, often involving billions of dollars per facility.

Alongside automakers, battery producers, energy providers, and tech companies are increasingly central players in this ecosystem. Partnerships and joint ventures are becoming common, especially for gigafactories and component plants. This inter-industry collaboration ensures that EV production capacity keeps pace with market demand while securing local and regional supply resilience.

The Role of Ancillary Industries and Government Incentives

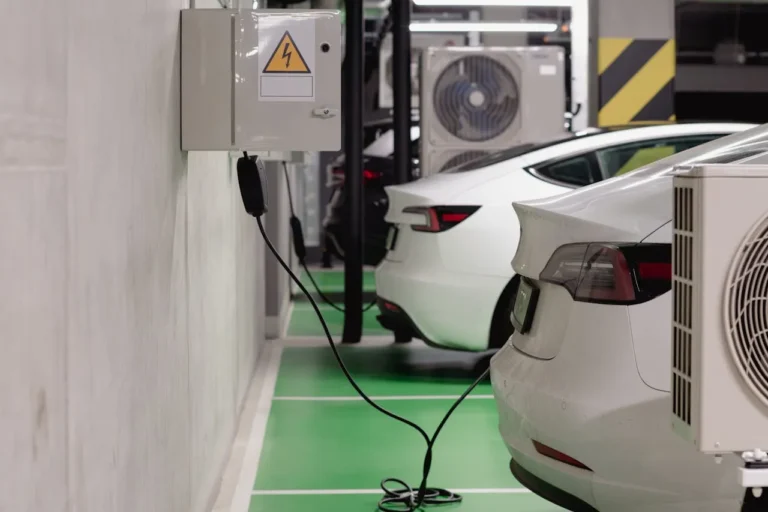

The growth of EV plant construction is also fueled by the rising importance of supporting industries—from battery supply chains and raw material processing to charging infrastructure and advanced vehicle electronics.

Governments worldwide are providing substantial incentives and subsidies for EV adoption, which often include tax credits, grants, or low-interest loans for constructing EV plants. Additionally, stricter emissions regulations are pushing automakers to accelerate their transition. These policies highlight the urgency of building specialized facilities that can deliver not only vehicles but also localized ecosystems for sourcing and processing critical materials.

For example:

- Europe has tied much of its EV industrial strategy to energy independence and sustainability goals.

- China continues to dominate battery supply chains by hosting some of the world’s largest EV component plants.

- The United States, through measures like the Inflation Reduction Act (IRA), is actively reshoring and localizing EV production to reduce reliance on imports.

Technology’s Impact on Modern EV Plant Design

A defining feature of today’s EV plants is their deep integration of cutting-edge technology. Automation, robotics, and artificial intelligence (AI) are transforming plant efficiency and output quality.

- Robotics are used extensively in battery module assembly, vehicle bodywork, and high-precision welding tasks.

- AI-driven predictive maintenance minimizes downtime by identifying potential failures before they disrupt production.

- 3D printing and additive manufacturing are enabling faster prototyping and customized tooling, cutting costs while shortening time-to-market.

- Modular construction methods allow companies to build and expand factories more rapidly, providing scalability as demand increases.

Another important dimension is the emphasis on green manufacturing. Many new facilities are designed as “net-zero” or “low-carbon” plants, powered partly or entirely by renewable energy sources like solar, wind, or hydro. This is particularly critical for EV battery manufacturing, which is highly energy-intensive. Automakers recognize that the carbon footprint of production is under growing scrutiny, making green plants a competitive advantage.

Benefits of Specialized EV Plants

Unlike retrofitted ICE facilities, purpose-built EV plants are optimized to handle the unique requirements of EV production. Dedicated lines for battery packs, electric drivetrains, and modular vehicle platforms allow smoother integration of advanced components while maintaining high safety and quality standards.

Key benefits include:

- Scalability – Plants can expand capacity or adapt to new EV models quickly.

- Efficiency – Streamlined workflows reduce energy consumption and operational costs.

- Resilience – Localized supply and production capabilities reduce dependence on global logistics bottlenecks.

- Sustainability – New facilities incorporate eco-friendly designs and renewable power from the start.

For automakers, these factors translate into lower costs, faster production, and stronger competitiveness in an increasingly crowded EV market.

Market Drivers and Growth Catalysts

Several factors underpin the expected 8.2% CAGR in EV plant construction:

- Rising EV Demand

- Global EV adoption is accelerating, requiring massive production expansion.

- Government Policies and Incentives

- Subsidies and regulations are forcing manufacturers to invest in EV-dedicated capacity.

- Technological Advancements

- Automation, robotics, AI, and renewable integration are making plants more efficient and sustainable.

- Supply Chain Localization

- Vertical integration and local production of batteries and components are reducing reliance on imports.

- Sustainability Goals

- Automakers are committing to carbon neutrality and need eco-friendly facilities to achieve these targets.

Market Segmentation and Regional Trends

The report highlights key segments by type and end-use:

- By Plant Type

- Assembly Plants

- Battery Manufacturing Plants

- R&D Centers

- Charging Infrastructure Facilities

- By End-Use

- Automakers

- Battery Manufacturers

- Charging Infrastructure Providers

- Other Industry Participants

Segment Highlights:

- The Assembly Plant segment is projected to reach US$26.8 billion by 2030, expanding at a CAGR of 7.8%.

- Battery Manufacturing Plants will grow even faster, with a CAGR of 9.6%, reflecting the strategic importance of localized battery supply.

Regional Analysis:

- The U.S. market is valued at US$10.5 billion in 2024 and continues to expand with strong government support.

- China, already the global leader in EV production, is forecast to grow at a CAGR of 8.0%, reaching US$10.3 billion by 2030.

- Europe, Japan, and Canada also remain critical hubs, particularly for sustainable plant innovation and advanced R&D centers.

- Asia-Pacific and Latin America are emerging as fast-growth regions, benefiting from rising consumer adoption and industrial investments.

Key Players Shaping the Industry

The competitive landscape includes global engineering and construction giants as well as regional leaders. Some of the 40+ featured companies are:

- Acciona S.A.

- AECOM

- Bechtel Corporation

- Bouygues Construction

- Hensel Phelps

- Hyundai Engineering & Construction (Hyundai E&C)

- Kiewit Corporation

- Larsen & Toubro Ltd.

- PCL Constructors Inc.

- Samsung C&T Corporation

These companies are increasingly positioning themselves as partners to automakers, offering not just construction expertise but also integrated solutions in sustainability, energy management, and digital automation.

Emerging Trends Reshaping EV Plant Construction

The report identifies several transformative trends:

- Vertical integration: Automakers building in-house battery and component facilities.

- Modular and flexible manufacturing lines: Designed to adapt quickly to new EV models.

- AI-driven predictive maintenance: Increasing efficiency and minimizing downtime.

- Green building practices: Growing adoption of sustainable materials and renewable-powered operations.

- Advanced robotics: Expanding role in high-precision assembly tasks.

Together, these trends underscore the industry’s shift toward faster, smarter, and greener manufacturing systems.