Yamaha has taken a significant step toward broadening the visibility and commercial reach of its advanced manufacturing capabilities with the launch of a new Yamaha Marine Systems Company, Inc. (YMSC) website. Designed to showcase the depth, scale, and technical sophistication of Yamaha’s U.S.-based manufacturing resources, the new portal highlights capabilities that extend well beyond traditional marine applications. By bringing together detailed overviews of Yamaha Marine Precision Propellers (YPPI) in Greenfield, Indiana, Bennett Marine in Deerfield Beach, Florida, and Yamaha Marine Rotational Molders (YMRM, formerly Kracor) in Milwaukee, Wisconsin, the website positions YMSC as a unified, integration-focused manufacturing organization serving both marine and adjacent industries.

A Strategic Platform for Manufacturing Visibility and Growth

The launch of the YMSC website reflects Yamaha’s broader strategy of leveraging its manufacturing expertise across multiple sectors while maintaining the high quality and reliability associated with the Yamaha brand. Rather than focusing solely on end products, the site emphasizes manufacturing processes, engineering depth, and production scalability. This approach allows Yamaha to communicate directly with original equipment manufacturers (OEMs), industrial partners, and adjacent-market customers who may not traditionally associate Yamaha with contract manufacturing or component-level production. The website functions as both a marketing platform and an informational resource, detailing how YMSC’s facilities operate individually and collectively to deliver precision-engineered components at scale.

Yamaha Marine Systems Company: An Integration-Focused Organization

Established in 2017, Yamaha Marine Systems Company, Inc. was created to integrate several specialized manufacturing entities under a single strategic umbrella within Yamaha’s U.S. Marine Business Unit. YMSC unites Yamaha Marine Precision Propellers, Bennett Marine, Yamaha Marine Rotational Molders, and Siren Marine, enabling cross-functional collaboration and shared manufacturing excellence. The integration model allows Yamaha to optimize production efficiency, standardize quality systems, and apply advanced manufacturing technologies across facilities while preserving the unique expertise of each division. The new website reinforces this structure by clearly outlining how each subsidiary contributes distinct yet complementary capabilities to the overall YMSC value proposition.

Highlighting Core Capabilities Across Three Specialized Facilities

At the center of the YMSC website is a detailed presentation of the core competencies housed within YPPI, Bennett Marine, and YMRM. Each facility is presented not simply as a standalone manufacturer, but as part of a broader ecosystem designed to support complex, multi-material product development. The site explains how precision casting, custom metal fabrication, and rotational molding can be combined or deployed independently to meet diverse customer requirements. By framing these capabilities in a unified way, Yamaha underscores its ability to support full lifecycle manufacturing needs, from early-stage engineering support through high-volume production and finishing.

Leadership Perspective on Expansion and Opportunity

According to Ben Speciale, President of the Yamaha U.S. Marine Business Unit, the new website plays a critical role in unlocking future growth opportunities for YMSC. He emphasized that the three YMSC facilities offer advanced manufacturing capabilities capable of delivering scalable products not only for the marine industry, but also for adjacent markets with similar performance and durability requirements. By promoting the core competencies of each division through a centralized platform, Yamaha is positioning YMSC for expansion into new applications and partnerships while reinforcing its reputation for quality-driven manufacturing.

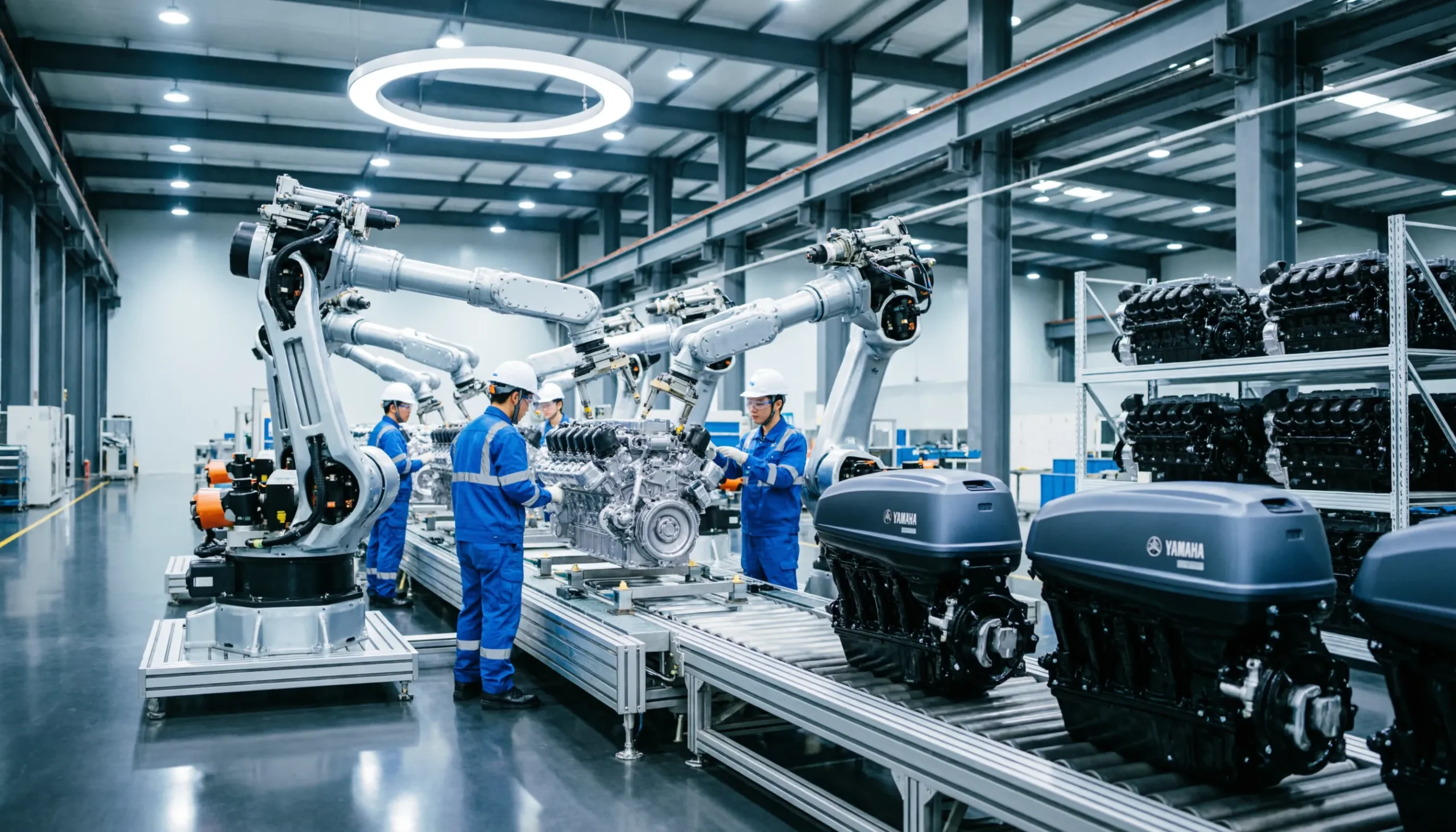

Yamaha Marine Precision Propellers: Advanced Investment Casting Excellence

Yamaha Marine Precision Propellers (YPPI) stands out as one of the most technologically advanced investment casting facilities in the United States. Built on decades of investment in equipment, workforce development, and quality systems, YPPI represents the pinnacle of Yamaha’s metal casting expertise. The facility specializes in stainless steel propellers, but its capabilities extend far beyond marine propulsion components. Through a concurrent engineering approach, YPPI integrates design, tooling, casting, and finishing processes under one roof, enabling rapid iteration, tighter tolerances, and enhanced product consistency.

Digital Traceability and Automated Production at YPPI

One of YPPI’s defining strengths is its emphasis on digital manufacturing and traceability. The facility offers full data traceability across the production process, supported by real-time digital monitoring systems that track quality metrics and process variables. Automation plays a central role, with features such as automated shelling systems, automated casting operations, and automated de-gating and grinding. These technologies not only improve efficiency and repeatability, but also support Yamaha’s commitment to continuous improvement and defect reduction. Advanced post-cast capabilities, combined with in-house CAD, simulation services, and patterned molding solutions, allow YPPI to deliver complex components with high structural integrity and surface finish.

Bennett Marine: Precision Metal Fabrication and Assembly

Bennett Marine contributes a different yet equally critical set of capabilities to the YMSC portfolio. Known for its expertise in trim tabs and marine control systems, Bennett Marine offers precision metal fabrication and complex assembly solutions that are adaptable to both high-volume production and specialized, lower-volume programs. The facility’s advanced equipment includes fiber laser cutting systems, robotic welding cells, and precision press brake forming technology, enabling tight tolerances and consistent quality across a wide range of metal components.

Integrated In-House Capabilities at Bennett Marine

Beyond fabrication, Bennett Marine’s value lies in its vertically integrated approach to manufacturing. In-house services include stainless steel electropolishing, wire harness assembly, electronic controls assembly, and comprehensive parts kitting and final assembly. This integration reduces supply chain complexity for customers while improving lead times and quality control. By maintaining these capabilities internally, Bennett Marine can support rapid product development cycles and customization requirements, making it an attractive partner for OEMs seeking reliable, U.S.-based manufacturing solutions.

Yamaha Marine Rotational Molders: Five Decades of Plastics Expertise

As the plastics-focused division of YMSC, Yamaha Marine Rotational Molders brings more than 50 years of experience in custom rotational molding. Formerly known as Kracor, YMRM has built a reputation for producing complex, hollow-body plastic components designed to withstand harsh operating environments. Serving marine, industrial, agricultural, and recreational markets, YMRM specializes in parts that require durability, UV stability, and dimensional precision. The facility’s long-standing expertise allows it to support both high-volume production programs and specialized applications with demanding performance requirements.

Engineering Support and Secondary Operations at YMRM

YMRM’s capabilities extend well beyond basic molding operations. The facility offers in-house mold design and engineering support, enabling close collaboration with customers during the product development phase. Secondary operations such as CNC trimming, component integration, and final assembly further enhance YMRM’s ability to deliver finished or near-finished products. This end-to-end approach positions YMRM as a trusted domestic manufacturing partner for OEMs seeking quality, scalability, and engineering collaboration in plastic component production.

Expanding Beyond Marine into Adjacent Markets

A key theme of the new YMSC website is the applicability of Yamaha’s manufacturing capabilities to industries beyond marine. The processes used at YPPI, Bennett Marine, and YMRM are well suited to sectors such as industrial equipment, agriculture, outdoor recreation, and specialty transportation. By highlighting these cross-market applications, Yamaha signals its intent to diversify manufacturing partnerships while leveraging existing investments in automation, engineering, and quality systems. This strategy not only supports revenue growth, but also strengthens the resilience of Yamaha’s U.S. manufacturing footprint.

Yamaha U.S. Marine Business Unit: A Broader Context

Yamaha Marine Systems Company operates within the larger Yamaha U.S. Marine Business Unit, headquartered in Kennesaw, Georgia. The business unit markets and sells a comprehensive range of marine products, including outboard motors from 2.5 to 450 horsepower, boat control systems, IoT-enabled control devices, fiberglass and jet-drive sport boats ranging from 19 to 29 feet, and personal watercraft. In addition to product development and sales, the unit oversees multiple manufacturing divisions, including Yamaha Marine Systems Company, Inc., Yamaha Marine Rotational Molders, Bennett Marine, Siren Marine, and Yamaha Marine Precision Propellers.

Strengthening Yamaha’s U.S. Manufacturing Footprint

As a division of Yamaha Motor Corporation, U.S.A., based in Cypress, California, the Yamaha U.S. Marine Business Unit plays a critical role in Yamaha’s global manufacturing and innovation strategy. The launch of the YMSC website underscores Yamaha’s commitment to domestic manufacturing excellence, advanced production technologies, and long-term investment in U.S. facilities. By clearly articulating the capabilities and strengths of its manufacturing subsidiaries, Yamaha is not only enhancing transparency, but also creating new pathways for collaboration and growth across industries.

A Platform for Future Collaboration and Innovation

Ultimately, the new Yamaha Marine Systems Company website serves as more than a digital brochure. It is a strategic platform designed to communicate Yamaha’s manufacturing philosophy, technical depth, and readiness to support complex production challenges. By unifying its precision casting, metal fabrication, and rotational molding capabilities under a single, accessible portal, Yamaha positions YMSC as a versatile manufacturing partner capable of meeting evolving market demands. As industries continue to seek reliable, high-quality domestic manufacturing solutions, YMSC’s integrated approach and proven expertise place it in a strong position for sustained expansion and innovation.

Source Link:https://www.businesswire.com/